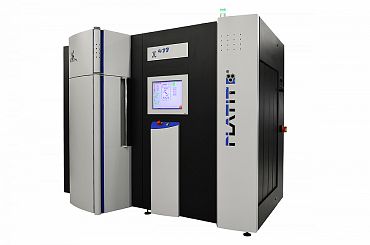

Apparatuses for vacuum metal coating and application of layers

We offer design and manufacture of vacuum equipment for metal coating and layer application according to your specific requirements. The produced equipment is used for application of thin layers onto glass, plastics, ceramics or metals in the industries of optics, electrical engineering or automobile, for jewellery and in the mechanical engineering. Utilization examples can be: application of resistant layers onto cutting tools, special mirror manufacturing or decorative purposes in the glass industry, creation of optical layers on lens and mirrors in the optics, application of reflecting layers in the automobile industry.

Technology and design

The apparatuses for vacuum metal coating and thin layer application are mostly provided with the technology of steaming by means of resistance evaporators or powder process using magnetrons. A matter of course is process equipment automatic control based on measurements and evaluation of applied layers. The characteristic features of the manufactured apparatuses are their outstanding mechanical design and industrial computer control with the option of process equipment data archiving.

The vacuum components are designed in our own designing and technical department equipped with modern computer technology for future product 3D modelling, designing and testing, creation of production documentation. In the course of the development and design we collaborate with leading world producers of components.

Manufacture

Our production consists in manufacture in pieces and in series according to technical documentation made by ours or by the customer. The production basis is premises modern equipment with machines, measurement instrumentation and testing apparatuses. The overall equipment and spatial possibilities, good organization of the manufacture and the long-term economic stability of the company enable implementation of large-scale contracts.

Guarantee of high quality

Technical perfection and high quality of our products is based on long-term experience of our design and development personnel, experience, skill and dexterity of all our production workers, careful selection of used materials and components, constant adherence to production methods pursuant to standards ISO 9001 and ISO 14001. In our products, the following is an absolute matter of course:

- Functionality test and measurement

- Product quality check

- Final checking and revision

- Declaration of conformity

- Guarantee

- Service